FATSO - Anaerobic Adhesives and Sealants

|

Fasto anaerobic adhesives and sealants are developed to maximize efficiency and to minimize the need for machinery maintenance in your facility. Curing only in the absence of oxygen and in the presence of metal ions, Fasto anaerobic adhesives are a solvent-free, room-temperature cure, one component system designed to deliver metal-to-metal bonds that resist shock and vibrations.

Fasto adhesives are unique due to their different strength properties and may be categorized as being high, medium, or low-strength, making selection of the appropriate product simple within a given category of use. General uses of Fasto anaerobic adhesives include locking and sealing of fasteners, retaining cylindrical assemblies like shaft-gear, shaft-bearing, shaft-pulley, rotors & many more, gasketing of flanges and sealing of pipes.

|

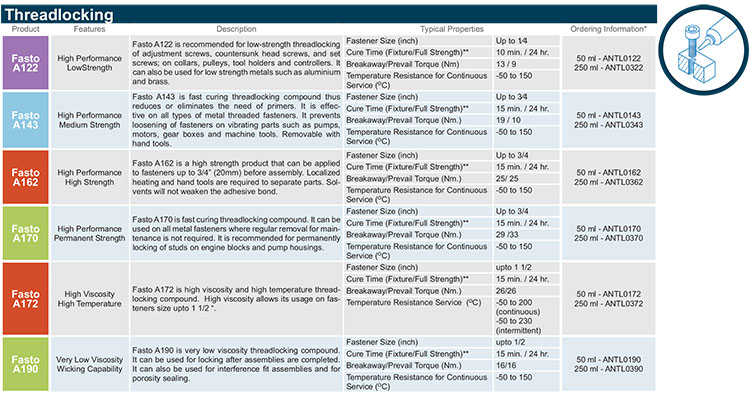

THREADLOCKERS |

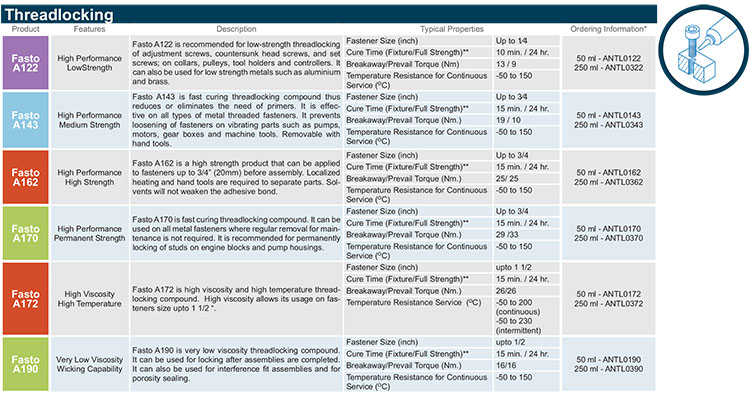

Vibration often causes self-loosening of threads; our Fasto anaerobic adhesives provide a simple solution to this problem. When the appropriate Fasto thread locker is applied and the parts are then assembled, the thread locker fills the voids in the threads, locking bolts in place and creating a corrosion-stopping seal.

Fasto threadlockers are designed to eliminate the need for mechanical aids like washers, check nuts etc, in securing threads. When choosing which Fasto threadlocker to use, consideration should be made for the various strength classes available, together with the substrate and size of the threads to be bonded. While most Fasto threadlockers are designed to be non-removable, low-strength grades are available to allow future disassembly. Fasto threadlockers are also available in a variety of viscosities, from wicking-grade to gel.

|

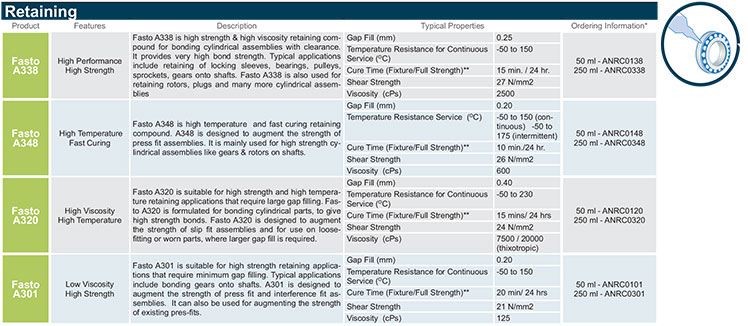

Retaining Bearings, Shafts, Studs and Flanges |

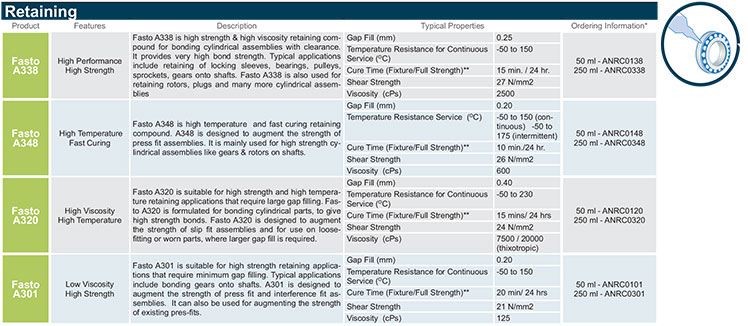

Fasto retaining compounds durably and reliably retain cylindrical assemblies like shaft-gear, shaft-bearing, shaft-pulley, rotors & many

more. Generally speaking, the need to dismantle such joints is not required, and Fasto retaining compounds are designed for high strength to meet this requirement. When Fasto retaining compounds are used, it is possible to achieve uniform stress distribution throughout the joint, making it possible to withstand dynamic and static loads with equals ease.

Additionally, use of Fasto retaining compounds confers the following advantages on the joints they bond:

- Small gaps can be bridged, which allows for less costly part designs

- Friction corrosion is avoided

- Allows assembly of parts with different elongation figures.

|

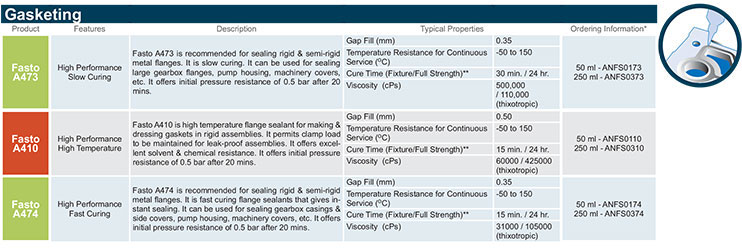

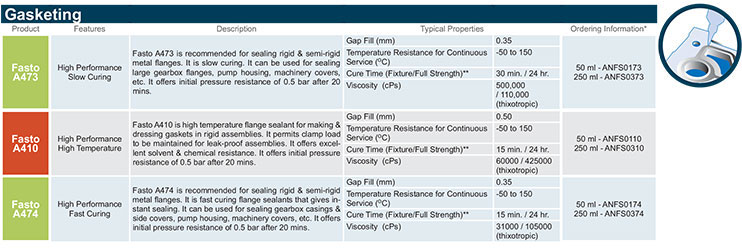

Sealing GasketsFasto gasket makers help eliminate pre-cut or compression gaskets. Used to fill the voids between metal flanges, Fasto gasket makers

create a seal that protects the joint against corrosion. Because Fasto gasket makers are available in different strengths, it gives part designers freedom to design different types of joints-for example, one that is easy to disassemble, or one with the higher mechanical resistance conferred by simple choosing a higher-strength gasket maker. Fasto gasket makers are resistant to many common oils and gases, and permit sealing tests of up to 1 bar immediately after the parts are fully assembled.

Another great advantage of Fasto gasket makers is that they eliminate joint settlement. Compared to traditional rigid flanges, there is no need to re-tighten the flange bolts, and creeping and shimming effects are eliminated. Fasto gasket makers also allow you to reduce inventory by providing a single liquid solution to all your gasketing needs.

|

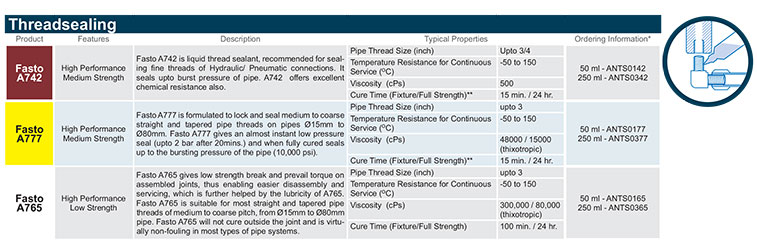

Sealing Pipes |

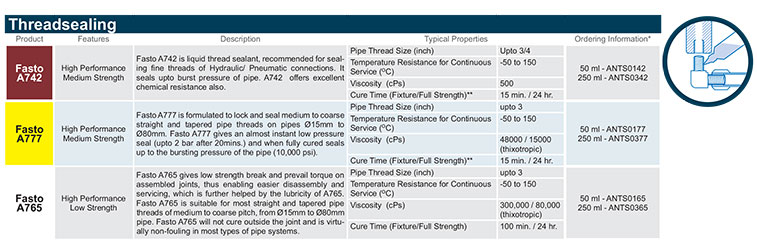

In addition to sealing fine threads, Fasto pipe sealants can also seal pipe fittings. Thanks to their ability to withstand most chemicals, these

sealants provide a complete seal between threads, offering many advantages over traditional sealing methods like PTFE tape or hemp. Depending on which sealant has been selected, initial leak tests may be carried out immediately, though early testing should not exceed 1 -2 bar. After curing is complete, pressure can be maximized, and the sealant will hold until the joint is destroyed.

As with any anaerobic adhesive or sealant the substrates to be bonded and their design have a huge influence on which Fasto pipe sealant is most appropriate for use. For example, larger threads need more adhesive to fill their larger voids, and will give higher torque values once the sealant is fully cured. In this instance, a low-strength Fasto pipe sealant should be selected, especially if easy disassembly is required.

|

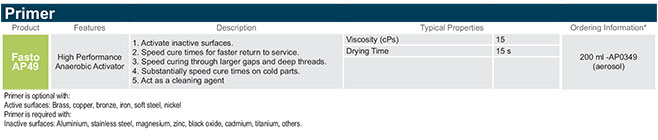

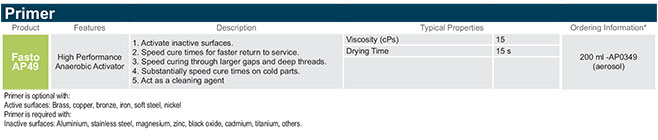

Primer |

|

|

"Product Range"

TDS Fasto 1313 - Electrical & Electronics Contact Cleaner  |

TDS Fasto 1411 - ElectroKote  |

TDS Fasto A122 - THREADE LOCKER LOW STRENGTH |

TDS Fasto A142 - THREADE LOCKER MIDIUM STRENGTH |

TDS Fasto A143 - THREADE LOCKER OIL RESISTANT GRADE |

TDS Fasto A162 - THREADE LOCKER HIGH STRENGTH |

TDS Fasto A170 - THREADE LOCKER PERMANENT STRENGTH |

TDS Fasto A171 - THREADE LOCKER HIGH TEMRATURE AND GOOD STRENGTH

|

TDS Fasto A172 - THREADE LOCKER HIGH PERFORMANCE GRADE

|

TDS Fasto A190 - THREADE LOCKER WICKING GRADE |

TDS Fasto A301 - RETAINING ANEROBICS

|

TDS Fasto A320 - RETAINING |

TDS Fasto A338 - RETAINING HIGH STRENGTH APPLICATIONS |

TDS Fasto A341 - RETAINING BEARING APPLICATIONS |

TDS Fasto A348 - RETAINING HIGH TEMRATURE

|

TDS Fasto A410 - GASKETING |

TDS Fasto A418 - GASKETING |

TDS Fasto A474 - GASKETING |

TDS Fasto A742 - THREADE SEALING UP TO 1 INCH PURPOSE |

TDS Fasto A765 - THREADE SEALING PTFE GRADE

|

TDS Fasto A777 - THREADE SEALING

|

TDS Fasto CA15 |

TDS Fasto UV52 |

TDS Fasto UV92 |

|